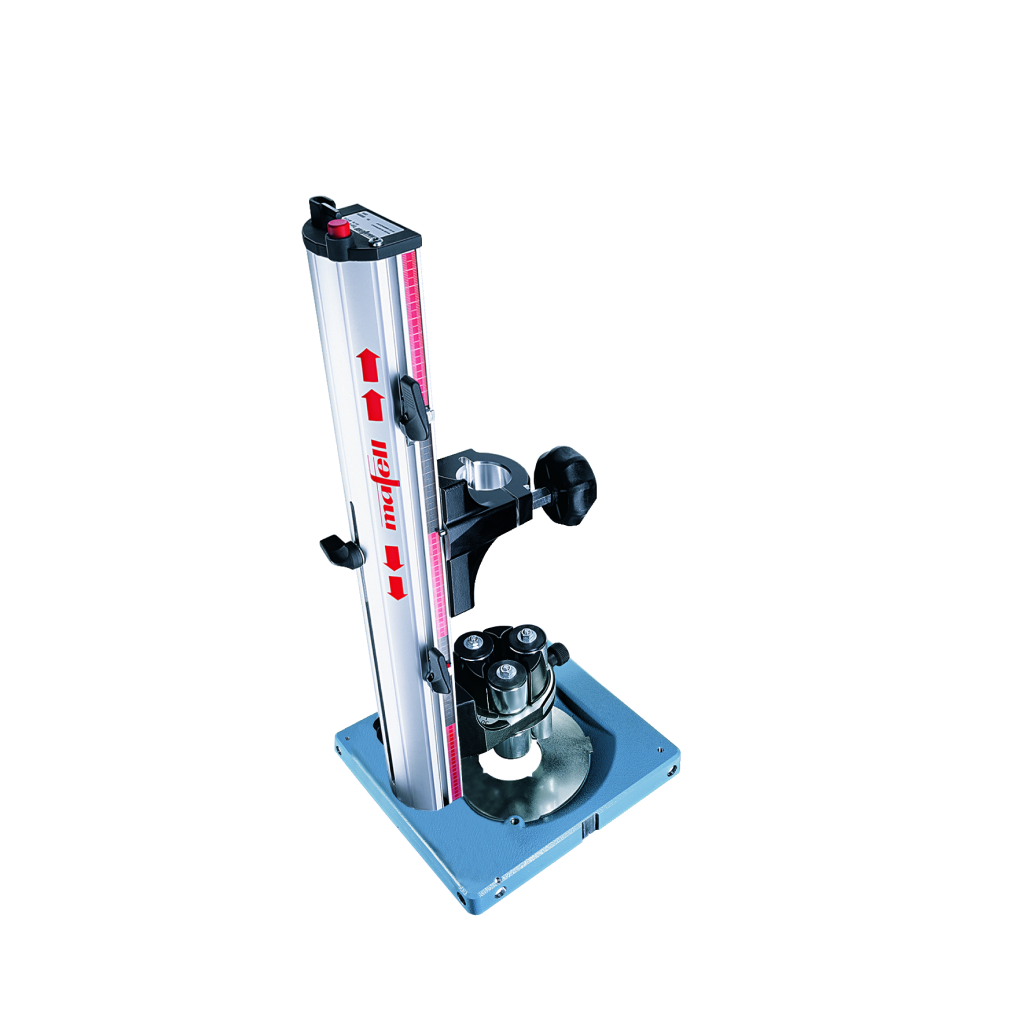

Order Number: 961211

With stop system thanks to parallel fence (See special accessories).

Technical Data:

| Max. Tool Diameter At 0° | 5-1 / 8″ 130 mm. |

| Max. Tool Diameter At 45° | 3 -15 / 16″ 100 mm. |

| Drill Guide Clamping Range | 5 / 16″ – 1 – 3 / 16″ / 8 – 30 mm. |

| Tilting Adjustment, Both Sides | 45 ° |

| Collar Diameter | 1 – 11 / 16″ / 43 mm. |

| Max. Drill Length | 18 – 1 / 8″ / 460 mm. |

| Max. Drilling Depth | 10 7/16′ / 265 mm |

| Weight | 5 Kg. |

Applications:

- Precision and series drilling;

- Angle drilling;

- Compatible materials include solid wood and laminated beams.

Advantages:

- The 80 mm. high drill guide comprises six vertically located rollers with an iris-like adjusting mechanism. They enclose the bit without any backlash and thus provide perfect guidance. This arrangement prevents the bit from drifting.

- The tensile force exerted by the polyethylene cable can be individually adjusted, for example, in order to reduce the feed pressure when working horizontally. Once the hole has been drilled, the machine automatically returns to the starting position.

- The S models can be precisely set to +/- 45° in either direction with the aid of a scale; and locked at 0°. The drill tip – at base plate height – always serves as the pivot axis.